Commercial and industrial building managers have the unenviable task of ensuring the proper control of multiple critical functions. The flow of liquids and gases, in particular, is a vital operational necessity that building managers must regularly inspect and validate.

This involves inspecting and confirming the suitability of numerous system components, from pressure switches and sensors to level monitoring equipment. Specifically, ball valves are among the most reliable and widely used flow control devices and ones which require regular oversight.

That said, ball valves remain some of the most widely misunderstood mechanical components in building management. This guide will explore what ball valves are, how they function, and their various applications.

Understanding Ball Valves

A ball valve is a mechanical device that controls the flow of liquids through a system using a hollow, perforated ball that pivots within the valve housing.

A ball valve design concept is simple: when the ball’s hole aligns with the flow direction, the valve is open.

When rotated 90 degrees, it completely blocks the flow.

How Do Ball Valves Work?

The operation of a ball valve is straightforward yet highly effective in pressure flow management applications. The key components include:

- Valve housing: The external casing that contains the internal components

- Central ball: A hollow, spherical component with a bore through its centre

- Valve seats: The seating that holds the ball securely in place

- Operating lever: The handle used to rotate the ball between positions

When the handle is turned, it rotates the ball on its axis, either allowing contents to flow through freely or blocking it completely. This quarter-turn operation makes ball valves particularly quick and easy to operate.

Types of Ball Valves

Different commercial and industrial applications require different types of ball valves. The main categories include:

Manual Ball Valves

These are operated by hand using a lever or handle, making them ideal for situations requiring direct operator control.

Process Ball Valves

Commonly used in instrumentation systems and industrial processes, these valves are designed for more demanding applications.

Pneumatic Ball Valves

These use compressed air for operation, making them suitable for automated systems.

Materials and Construction

Ball valves are manufactured using various materials to suit different applications, including (but not limited to):

- Stainless steel: Excellent for corrosive environments

- Brass: Common in plumbing applications

- PVC: Suitable for lower pressure applications

- Nickel-plated brass: Offers additional durability and corrosion resistance

Applications of Ball Valves

Ball valves find use across numerous industries and applications:

- Fire sprinkler systems (among a range of sprinkler system parts and components)

- Industrial cooling systems

- Gas distribution networks

- Manufacturing processes

- Chemical processing

- Water treatment facilities

- HVAC systems

- Oil and gas industry

Advantages of Ball Valves

Ball valves offer several key benefits that make them popular in industrial applications:

- Reliable Shut-off

The design provides excellent sealing capabilities when closed, ensuring complete flow stoppage.

- Durability

Ball valves are robust and can operate effectively for many years with minimal maintenance.

- Simple Operation

The quarter-turn mechanism makes them quick and easy to operate.

- Versatility

They can handle various elements and are suitable for both high-pressure and high-temperature applications.

What Are the Limitations of Ball Valves?

While ball valves are excellent for many applications, they do have some limitations:

- Less suitable for precise flow control between fully open and closed positions

- May require more torque to operate under high pressure

- Can be more expensive than some other valve types

Choosing the Right Ball Valve

When selecting a ball valve, consider these factors:

- Operating pressure: Ensure the valve can handle your system’s pressure requirements

- Temperature range: Check compatibility with your process temperatures

- Media type: Choose appropriate materials for your specific application

- Connection type: Consider whether you need threaded, flanged, or compression fittings

- Control requirements: Determine if you need manual or automated operation

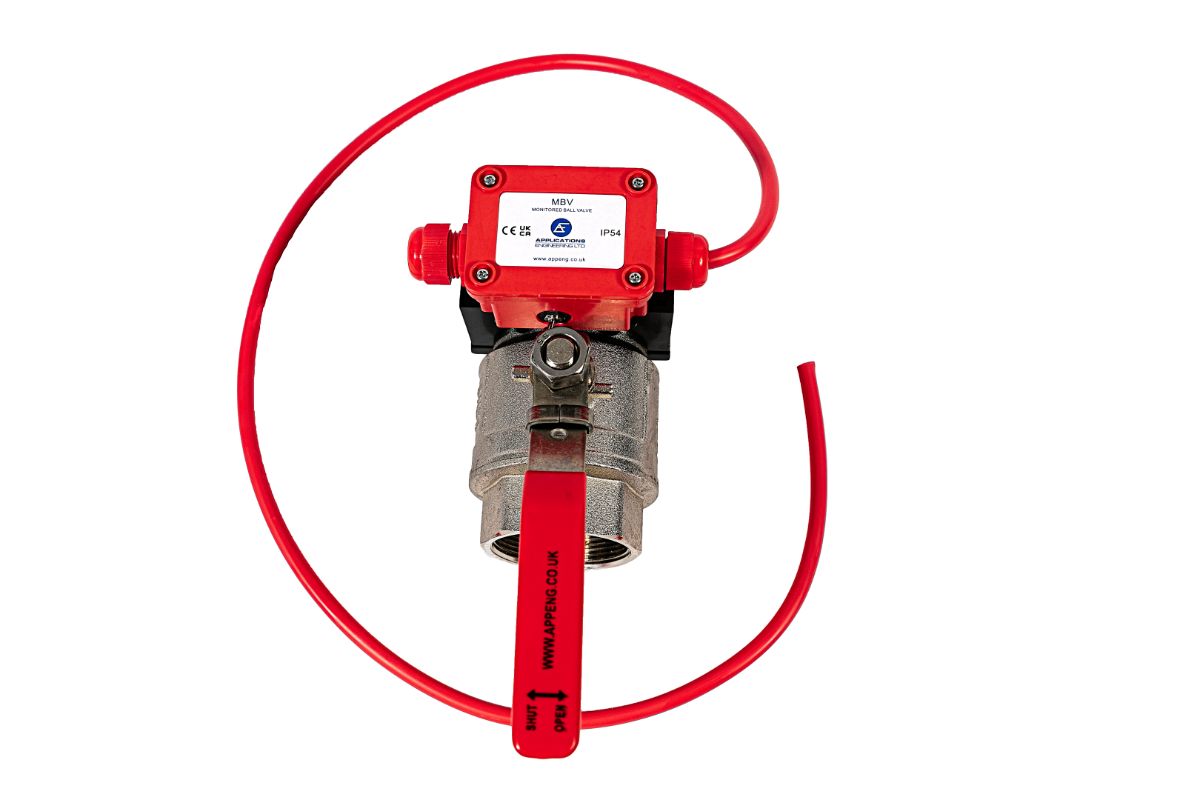

Expert Support from Applications Engineering

At Applications Engineering, we understand that selecting the right ball valve is crucial for your system’s efficiency and reliability. Our extensive range of high-quality ball valves is backed by our team’s expert knowledge and our ISO 9001 certified management system.

We maintain significant stock levels at our Sussex facility, ensuring quick delivery times and excellent product availability. Our experienced professionals can help you select the perfect ball valve for your specific application, considering factors such as pressure requirements, temperature ranges, and media compatibility.

Contact Applications Engineering today to discuss your requirements and discover how our expertise can benefit your operations.

Filed under: Advice and Information